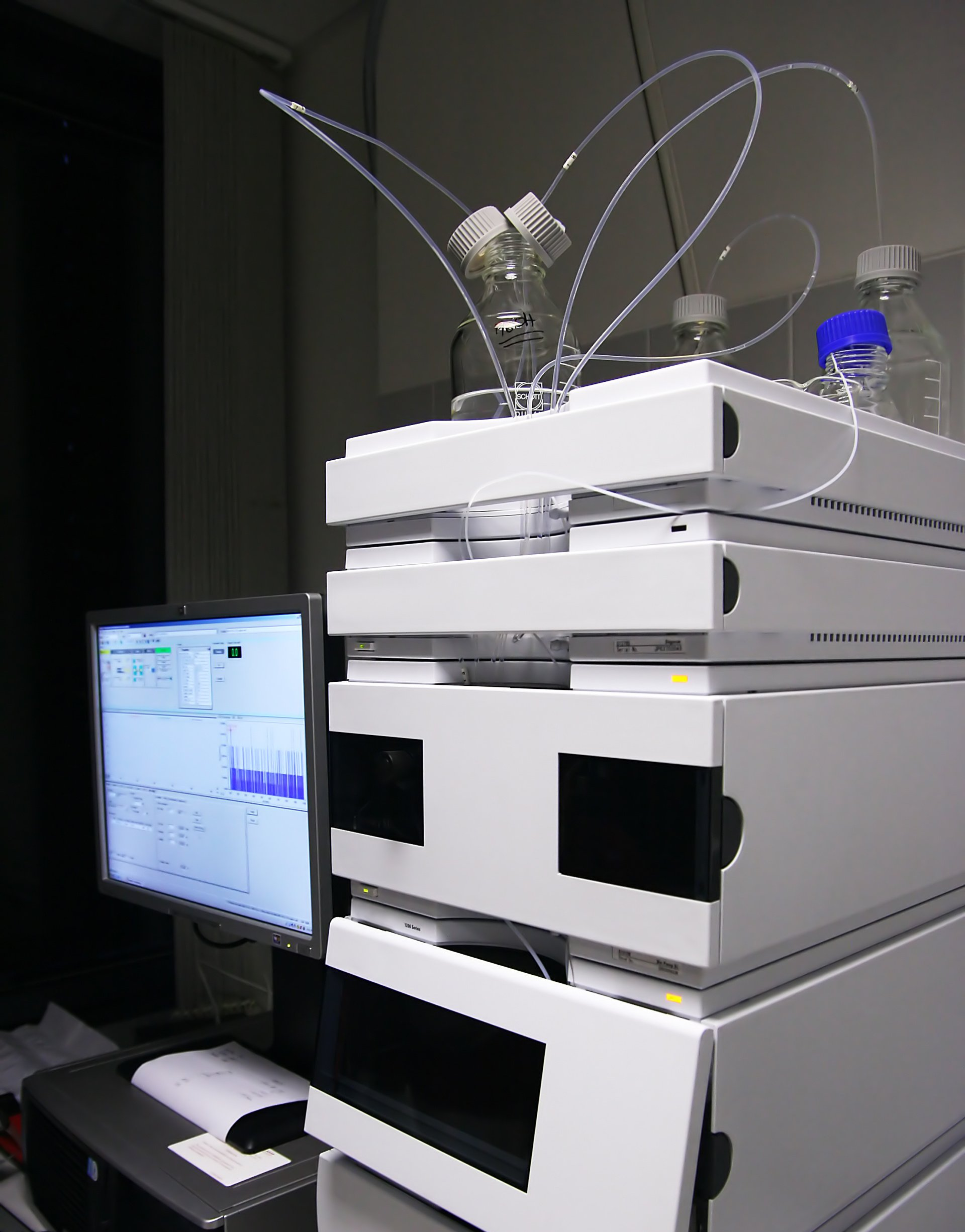

HPLC Instrumentation for Analysis: Identifying and Repairing Leaks

Ben Wartel, Overbrook Liquid Phase Engineer | November 16, 2020

Leaks are one of the most common issues you will encounter while operating an HPLC. Some leaks are easily observable as drops of liquid forming where a capillary nut meets a fitting. Other signs of a leak in the system can be lower than normal system pressure, fluctuating pressure, broadening peaks or peak tailing, longer than normal retention times, or the system telling you there is a leak, as most modern HPLCs come equipped with leak sensors. Leaks most frequently occur where capillaries are removed and refitted regularly, such as the fittings on either side of a column.

If the offending fitting is stainless steel, you can tighten it 1/8th of a turn with a wrench, observe whether the leak has stopped, and repeat as necessary. If a stainless-steel fitting continues to leak and cannot be tightened further, the ferrule must be replaced, or a new capillary must be installed if the old ferrule cannot be removed.

When you encounter a leaky PEEK fitting you should first turn off the pump flow, then loosen the nut and push the tubing into the bottom of the fitting body and re-tighten the nut (finger-tight only!). If it continues to leak, try cutting a new end to the PEEK tubing and re-fit the nut. As a last resort, replace the nut.

Keep in mind that the most common PEEK fittings are generally capable of holding only 6,000 bar of pressure, while most stainless-steel fittings are rated for up to 20,000 PSI. It is important to keep these numbers in mind along with the pressure ratings for the type of system you are running. The typical operating pressure for HPLCs is < 6,000 PSI. UPLCs are typically run between 6,000 and 15,000 PSI. Be sure to use fittings that can sustain adequate pressure for your system and methods. While finger-tight PEEK fittings are more convenient to disconnect and reconnect regularly, they may not be adequate for your UPLC methods.

Small leaks can be difficult to detect, especially if you are using a mobile phase that evaporates quickly. Such leaks may not be visibly observable, but they are often accompanied by the same symptoms of a large leak. If your mobile phase contains buffers, small leaks can be identified over time because they will leave residues behind. If you notice a white frosty/crystalline buildup at the end of a capillary or on any nuts, it’s a sign that you had or currently have a small leak occurring and you should take some of the remedial steps outlined above.

If you are unsure about where a small leak is occurring, methodically check the flow path by wiping the edge of a Kimwipe or thermal paper against fittings along the flow path and check for wetting. Thermal paper is especially effective for organic solvents, as it will turn black upon exposure. Start with the pump head, checking the inlet and outlet check valves, behind the pump heads (which would indicate worn plunger seals), check the purge valve and work your way through the flow path, moving to the ALS injection valve, needle, needle seat, and column compartment/column. Less critical are the column outlet, detector inlets and outlets (as most of the system backpressure should be before the column).

Any questions? Let us know. Our Liquid Phase specialists are here to help.