About GCMS

What is GCMS?

Ready to get started?

How Does GCMS Work?

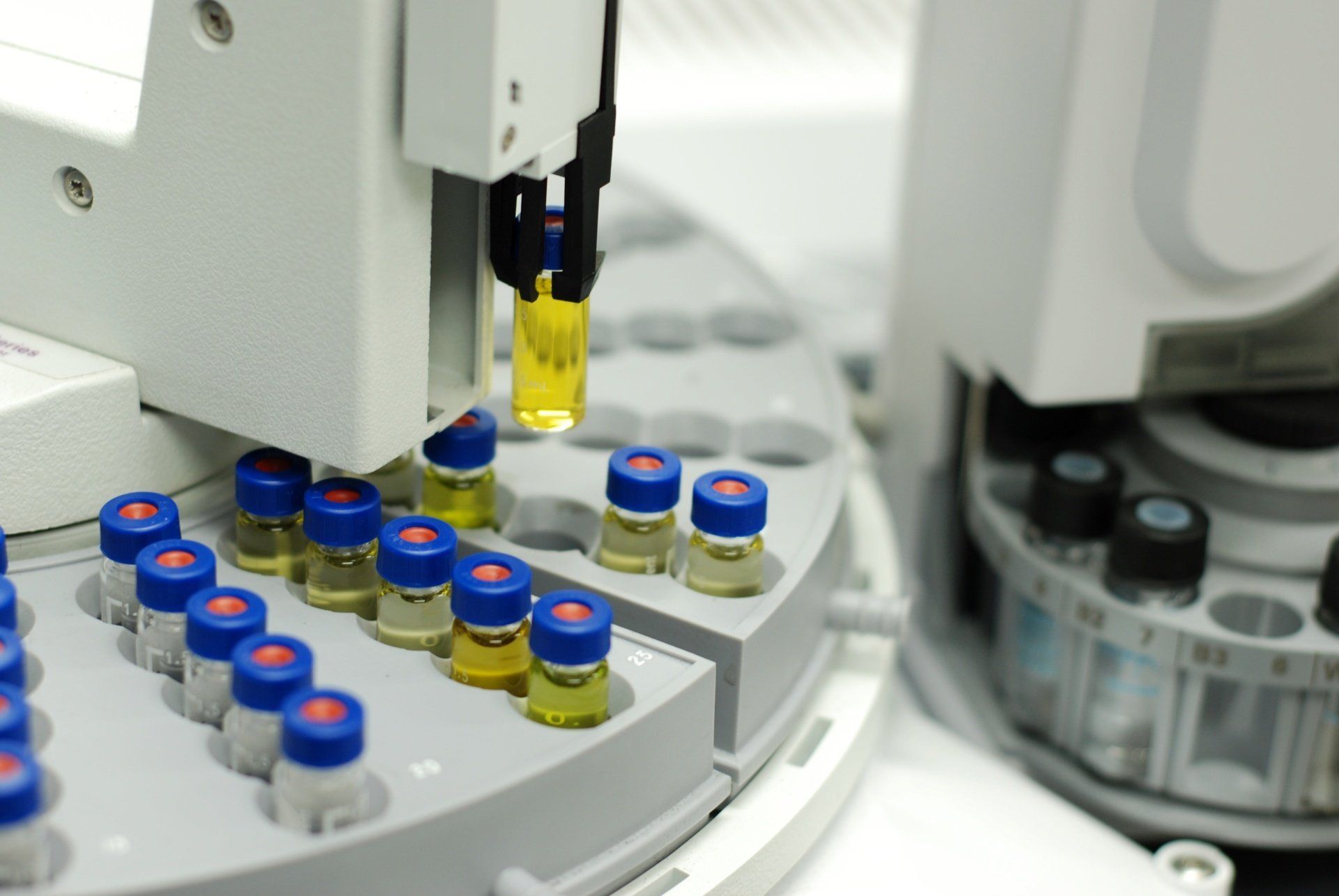

This process works by using an autosampler to introduce an extracted sample into a heated inlet . The analytes in the vaporized sample is introduced with a carrier gas and separated by molecular weight into individual analytes by traveling through a capillary column inside a heated oven at a selected temperature ramp rate and column flow. The Capillary Column is coated with a column phase which enables separation. Next, the compounds are forced by an inert gas like helium, argon, or nitrogen.

When the separated analytes exit the gas chromatography column they are ionized by the mass spectrometer with chemical or electron ionization sources. These ionized molecules are then sent to a mass analyzer (mass selective detector), typically a quadrupole or ion trap. This is the step where the ions become sorted in a vacuum based on their mass-to-charge ratios using electronic lenses and quadrapoles to attract or repel selected ions (masses).

There are two modes of operation Full Scan, in which all ions in a selected mass range are collected. The other is Selected Ion Monitoring (SIM) where only analytes of interest and their Identifying ions are selected and called for repeatedly in timed windows enabling a much lower detection limit with minimal interferences from non-target analytes.

Lastly, those selected ions or mass range are amplified in the electron multiplier and chromatographically displayed. Those detected and analyzed ions are associated with compound peaks representing their mass-to-charge ratios with the final results producing a mass spectrum. These spectra (EIC – extracted ion chromatograms and TIC Total Ion chromatograms can be compared to an established library of spectra to identify unknowns. Unknown chemicals can be identified with mass spectrometry by defining their unique structure.

Juggling is for Circuses.Are you focusing on too many things & not on your science?

What Can GCMS Analysis be Used For?

- Evaluating extracts from plastics

- Testing of residual solvents

- Finding trace impurities in gases and liquids

- Checking for organic pollutants in the environment

- Analyzing particles for criminal forensics and toxicology

- Detection of illegal drugs and substances

- And more

Why Should GCMS Assets be Serviced and Qualified?

To ensure that your instrumentation is performing at its highest level and providing accurate results, periodic and scheduled maintenance and qualifications must be addressed. Regular scheduled services such as Preventative Maintenance (PM) will ensure minimal system downtime, more productivity and peak performance.

In order to remain compliant with USP <1058>, qualifications must be conducted by an independent outsourced service provider. Qualification services can incorporate existing manufacturer protocol or your existing protocols for customization to fit the equipment’s intended use. Qualification services may include:

- Installation Qualification (IQ)

- Operational Qualification (OQ)

- Performance Qualification, (PQ)

- Repair Qualification (RQ)

Each of these services can be requested for the routine, scheduled qualification of laboratory systems, and for the first-time qualification or recently purchased GCMS assets.

It is essential to have qualifications done after a component repair or replacement, following a facility or instrument move, and when you are subject to inspection, audit, or review.